| Sign In | Join Free | My chinacomputerparts.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinacomputerparts.com |

|

Brand Name : CQT

Model Number : Fused Silica, Fused Quartz

Certification : ISO:9001, ISO:14001

Place of Origin : China

MOQ : 10 pcs

Price : Negotiable

Payment Terms : T/T

Supply Ability : 20000 pcs/Month

Delivery Time : 1-4 weeks

Packaging Details : Cassette/ Jar package, vaccum sealed

Material : Borofloat Glass

Brand : Schott Brorofloat 33

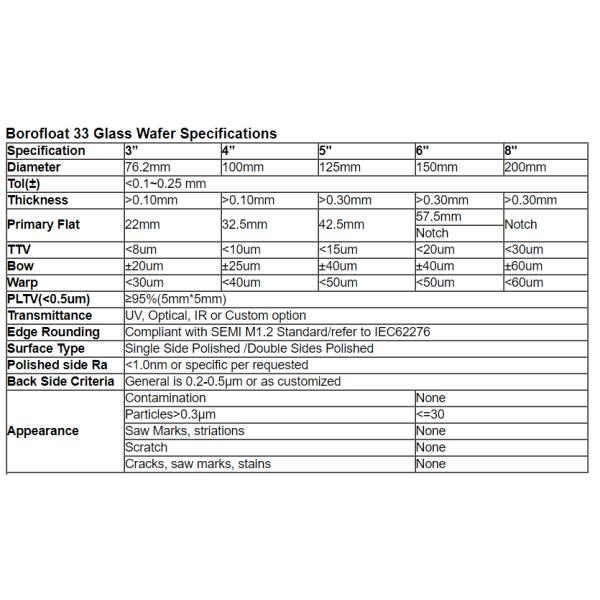

Diameter : 50.8mm 76.2mm 100mm 150mm 200mm

Thickness : 0.25mm 0.35mm 0.5mm, 0.725mm, 1mm

Edge : Round ground

Surface : DSP SSP

Refractive Index : 1.4585 (at 587.6 nm)

ApSemiconductor, MEMSplication : Electronics, Optics, And Semiconductors

Borofloat 33 Glass Wafers Engineered for Peak Thermal Stability, Exceptional Chemical Resistance, and Ultra-High Optical Clarity

Unlock precision and reliability with our premium Borofloat® 33 glass wafers—a leading choice for industries demanding superior thermal stability, optical clarity, and chemical durability. Engineered from borosilicate glass, these wafers excel in harsh environments, offering a low coefficient of thermal expansion (3.3 × 10⁻⁶/°C) that minimizes stress and distortion during rapid temperature changes.

Ideal for microfluidics, biotechnology, LED packaging, and semiconductor processes, Borofloat® 33 combines high-temperature resistance (up to 450°C) with excellent light transmission (92% from 350–2500nm). Its hydrophilic surface and biocompatibility make it perfect for lab-on-a-chip devices, while its hardness (Mohs scale 6) ensures long-lasting performance in demanding applications.

Available in diameters from 50mm to 300mm and thicknesses tailored to your needs, our wafers undergo stringent quality checks to guarantee flatness , surface finish, and dimensional accuracy.

Elevate your projects with Borofloat® 33—where innovation meets endurance. Contact us today for custom solutions and experience unmatched precision in every wafer.

Engineered for Excellence. Trusted by Innovators.

Glass Wafer Photos

FAQs:

A: We look at ourselves as the piezo wafer specialist. We are the very first to work with Single Crystal Quartz in China about 30 years ago. Then gradually we step in the field of LiNbO3, LiTaO3, Quartz glass, LGS, CTGS etc. Especially, if you are looking for a piezo quartz supplier, we are the ultimate choice! We export millions of quartz blanks each year because we master the AT, SC and IT cuts with superior angle precision.

A: Yes, of course. We can fabricate as per your request. In addition, we are so experienced with piezo wafers that we can provide you relevant suggestions if you are not 100% sure about your choice. Besides, we do have some standard wafers in stock, please check with us.

A: Yes, we would suggest you go with the courier agent you are most familiar with (DHL, FedEX, UPS etc.). We can ship via your account. And, of course, we will pack the products safely in acceptable size to help you save the shipping cost. If you need us to take care of the freight, it’s also not a problem. We also have good discount with the international courier companies.

A: The wafer products are fragile and sometimes expensive. The last thing, as the manufacturer, we want to see is the products we make were damaged during courier. As a result, we will pack the wafers adequately and put them in a proper carton filled with buffer sponge. However, accidents are inevitable sometimes. So, please follow the “Acceptance check” steps shown in the drawings below. If the unwanted happened, we will either give the replenishment or refund if you follow the checking steps.

A: Sure. Factory inspection is important for large quantity purchase and long-term cooperation. Face to face discussion is what we mostly confident with. During the past years, big names around the world have witnessed our progress in factory build-up. These days, due to the Covid-19 pandemic, we also had the experience of videoconferencing with global buyers.

Acceptance Check

|

|

Borofloat 33 Glass Wafers Engineered for Peak Thermal Stability, Exceptional Chemical Resistance, and Ultra-High Optical Clarity. Images |